Nitrogen Purification Equipment With Hydrogenation

High purity nitrogen was obtained by removing impurities such as oxygen, water, carbon dioxide and dust in nitrogen by catalytic deoxidation adsorption drying. Hydrogen, nitrogen and join after static mixed into the heat exchanger, using the deaeration tower export heat preheating in tone, and then enter the deaeration tower with efficient hydrogenation deoxidizing catalyst, the oxygen, nitrogen impurity react with hydrogen to generate water was removed, release a large amount of heat at the same time, 1% oxygen react when heat can form about 200 ℃ temperature. Then through the heat exchanger, and then into the dry filtration device to remove water, carbon dioxide and dust particles and other impurities, so as to obtain high purity nitrogen.

Key Specifications/Special Features

| 1 | capacity: | 10-20000Nm3/min |

| 2 | Nitrogen purity: | 299. 9995%. |

| Nitrogen Pressure. | 0.1-0.7MPa(adjustable) | |

| 3 | Oxygen content | ≤5ppm |

| 4 | Dust content: | ≤0.01um |

| 5 | Dew point: | ≤-60°C. |

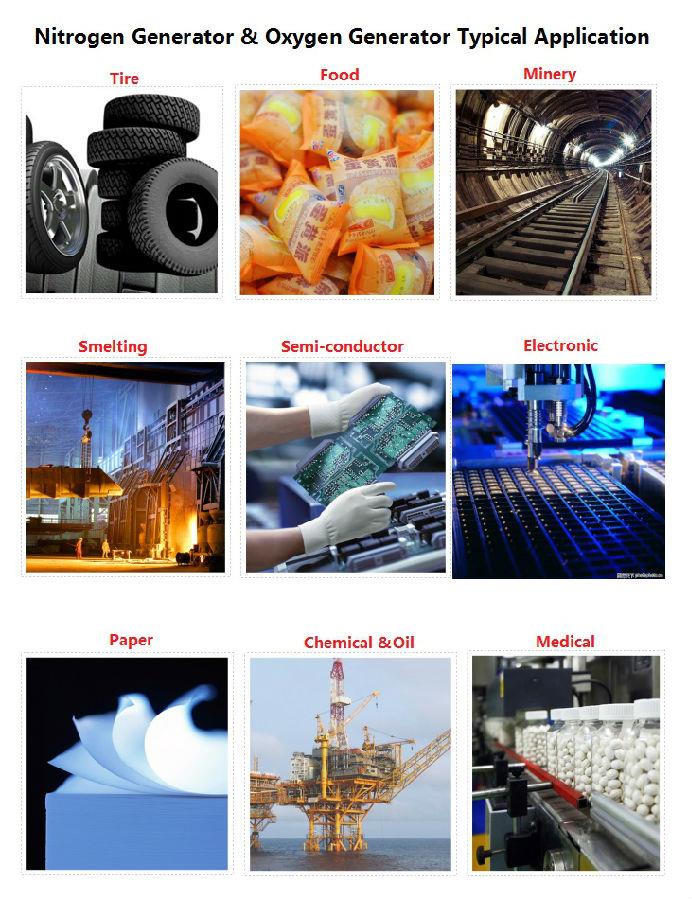

Applications

Widely used in metallurgical coal, power electronics, petrochemical, biological medicine, tire rubber, textile chemical fiber, grain depot, food preservation and other industries