High Purity oxygen generator oxygen generator manufacturers

Working Principle

Nitrogen molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and oxygen molecules have a slower diffusion rate. The diffusion of water and carbon dioxide in compressed air is similar to that of nitrogen. Finally, oxygen molecules are enriched from the adsorption tower. Pressure swing adsorption oxygen production uses the selective adsorption characteristics of zeolite molecular sieve, adopts the cycle of pressurized adsorption and decompression desorption, and makes the compressed air enter the adsorption tower alternately to realize the separation of oxygen and nitrogen, so as to continuously produce high-purity and high-quality oxygen.

PSA oxygen generator adopts high-quality zeolite as adsorbent according to the principle of pressure swing adsorption. Under a certain pressure, oxygen is extracted from the air, purified and dried compressed air, and pressurized adsorption and decompression desorption are carried out in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the micropores of zeolite molecular sieve is much higher than that of oxygen. Nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen. Then, after decompression to atmospheric pressure, molecular sieve desorbs the adsorbed nitrogen and other impurities to realize regeneration. Generally, two adsorption towers are set in the system, one for adsorption and oxygen production, and the other for desorption and regeneration. The PLC program controller controls the opening and closing of the pneumatic valve to make the two towers circulate alternately, so as to achieve the purpose of continuous production of high-quality oxygen.

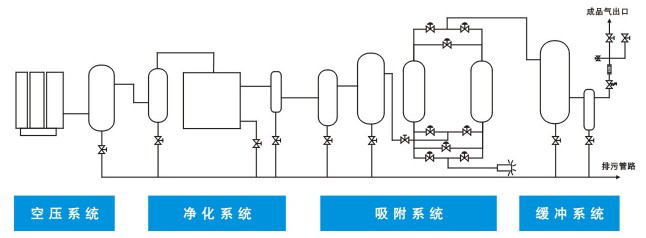

System flow

The complete oxygen generation system consists of the following components:

Air compressor ➜ buffer tank ➜ compressed air purification device ➜ air process tank ➜ oxygen nitrogen separation device ➜ oxygen process tank.

1. Air compressor

As the air source and power equipment of the nitrogen generator, the air compressor is generally selected as screw machine and centrifuge to provide sufficient compressed air for the nitrogen generator to ensure the normal operation of the nitrogen generator.

2. Buffer tank

The functions of the storage tank are: buffering, stabilizing pressure and cooling; So as to reduce the fluctuation of system pressure, fully remove oil-water impurities through the bottom blowdown valve, make the compressed air smoothly pass through the compressed air purification component, and ensure the reliable and stable operation of the equipment.

3. Compressed air purification device

The compressed air from the buffer tank is first introduced into the compressed air purification device. Most of the oil, water and dust are removed by the high-efficiency degreaser, and then further cooled by the freeze dryer for water removal, oil removal and dust removal by the fine filter, which is followed by deep purification. According to the system working conditions, hande company specially designed a set of compressed air degreaser to prevent possible trace oil penetration and provide sufficient protection for molecular sieve. The well-designed air purification module ensures the service life of zeolite molecular sieve. The clean air treated by this module can be used for instrument gas.

4. Air process tank

The function of air storage tank is to reduce air flow pulsation and buffer; So as to reduce the system pressure fluctuation and make the compressed air smoothly pass through the compressed air purification assembly, so as to fully remove oil-water impurities and reduce the load of subsequent PSA oxygen and nitrogen separation unit. At the same time, during the work switching of the adsorption tower, it also provides PSA oxygen and nitrogen separation unit with a large amount of compressed air required for rapid pressure rise in a short time, which makes the pressure in the adsorption tower rise to the working pressure quickly, ensuring the reliable and stable operation of the equipment.

5. Oxygen nitrogen separation unit

There are two adsorption towers a and B equipped with special molecular sieve for oxygen generator. When clean compressed air enters the inlet end of tower a and flows to the outlet end through molecular sieve, nitrogen is adsorbed by it, and product oxygen flows out from the outlet end of adsorption tower. After a period of time, the molecular sieve in tower a is saturated. At this time, tower a automatically stops adsorption, compressed air flows into Tower B for nitrogen absorption and oxygen production, and regenerates the molecular sieve of tower a. The regeneration of molecular sieve is realized by rapidly lowering the adsorption tower to atmospheric pressure and removing the adsorbed nitrogen. The two towers carry out adsorption and regeneration alternately to complete oxygen and nitrogen separation and continuously output oxygen. The above processes are controlled by programmable logic controller (PLC). When the oxygen purity at the gas outlet is set, the PLC program will open the automatic vent valve to automatically vent the unqualified oxygen, cut off the unqualified oxygen from flowing to the gas consumption point, and use the silencer to reduce the noise below 78dba during gas venting.

6. Oxygen process tank

The oxygen buffer tank is used to balance the pressure and purity of oxygen separated from the nitrogen oxygen separation system to ensure the continuous and stable supply of oxygen. At the same time, after the work switching of the adsorption tower, it recharges part of its own gas into the adsorption tower, which not only helps the pressure rise of the adsorption tower, but also plays a role in protecting the bed, and plays a very important process auxiliary role in the working process of the equipment.

Technical Parameters

Oxygen output: 5-300nm3 / h

Oxygen purity: 90% - 93%

Oxygen pressure: 0.3MPa

Dew point: - 40 ℃ (under normal pressure)

Technical Features

1. The compressed air is equipped with an air purification and drying treatment device. Clean and dry compressed air is conducive to prolonging the service life of molecular sieve.

2. The new pneumatic stop valve has fast opening and closing speed, no leakage and long service life. It can meet the frequent opening and closing of pressure swing adsorption process and has high reliability.

3. Perfect process design flow, uniform air distribution, and reduce the high-speed impact of air flow. Internal components with reasonable energy consumption and investment cost

4. The molecular sieve with high strength, high efficiency and low energy consumption is selected to intelligently control the unqualified oxygen venting system to ensure the oxygen quality.

5. The equipment has stable performance, simple operation, stable operation, high degree of automation, unmanned operation and low annual operation failure rate

6. It adopts PLC control, which can realize full-automatic operation. It can be equipped with oxygen device, flow, purity automatic regulation system and remote control system.

Application Field

1. EAF steelmaking: decarbonization, oxygen combustion heating, foam slag melting, metallurgical control and post heating.

2. Wastewater treatment: oxygen enriched aeration of activated sludge, pool oxygenation and ozone sterilization.

3. Glass melting: oxygen combustion and dissolution, cutting, increasing glass output and prolonging furnace life.

4. Pulp bleaching and papermaking: chlorine bleaching is transformed into oxygen enriched bleaching to provide cheap oxygen and sewage treatment.

5. Non ferrous metal smelting: oxygen enrichment is required for smelting steel, zinc, nickel and lead, and PSA method is gradually replacing cryogenic method.

6. Oxygen for petrochemical industry and chemical industry: oxygen enrichment is used to replace air for oxidation reaction in the oxygen reaction in petrochemical industry and chemical industry, which can improve the reaction speed and the output of chemical products.

7. Ore processing: used in gold and other production processes to improve the extraction rate of precious metals.

8. Aquaculture: oxygen enriched aeration can increase dissolved oxygen in water, greatly increase fish production, transport oxygen for live fish and intensively raise fish.

9. Fermentation: oxygen enrichment replaces air to supply oxygen for aerobic fermentation, which can greatly improve the efficiency of drinking water.

10. Ozone: provide oxygen to the ozone generator for self oxygen sterilization.

11. Hospital: provide bed breathing oxygen.The purity, flow and pressure are stable and adjustable to meet the needs of different customers.