Factory Cheap Hot Cold Box Air Separation Unit - Air separation, cryogenic air separation, cryogenic gas separation – Kejie

Factory Cheap Hot Cold Box Air Separation Unit - Air separation, cryogenic air separation, cryogenic gas separation – Kejie Detail:

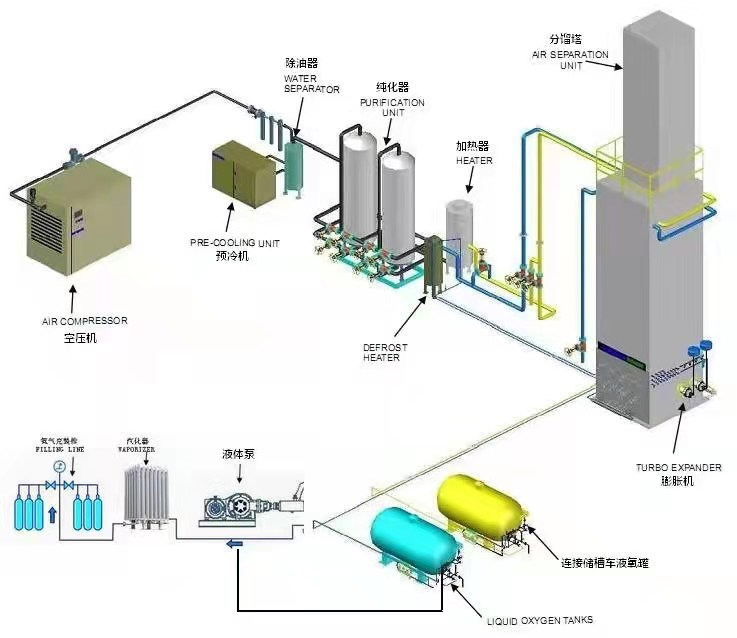

Process

1、Air Compressor: Air be compressed to 0.5-0.7Mpa by air compressor

2、Pre-cooling: The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated.

3、Air purification system:Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier;

4、Air expansion:The air expands and cools in the turbo expander and provides the cooling capacity required by the device

5、Heat Exchange:The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature;

6、Cooling:Cooling the liquid air and liquid nitrogen before the throttling of the nitrogen in the chiller.

7、Distillation:The air is rectified and separated in the rectification tower, and the product nitrogen is obtained at the top of the upper tower, and the product oxygen is obtained at the bottom of the upper tower.

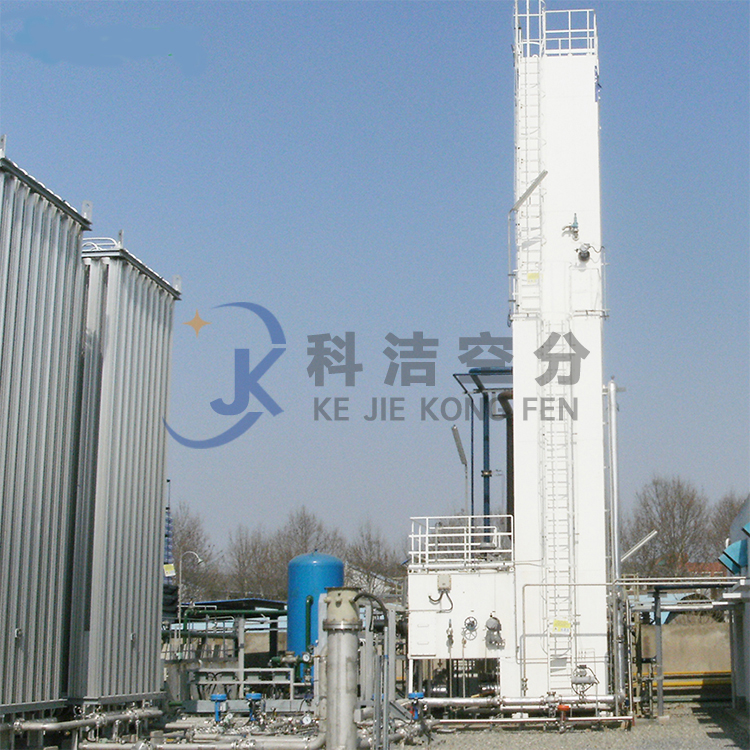

In order to meet the needs of the market, in addition to the production of conventional external compression air separation equipment, the company has also developed a series of internal compression air separation processes, which reduces the installation workload and equipment maintenance of the complete set of equipment.

The company designed and developed a skid-mounted purification system to minimize on-site piping installation time.

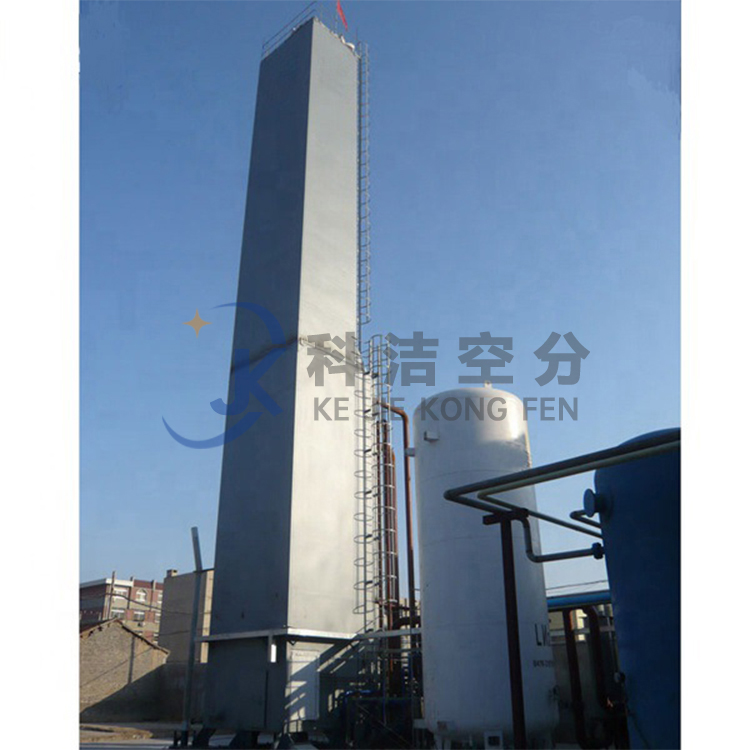

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Factory Cheap Hot Cold Box Air Separation Unit - Air separation, cryogenic air separation, cryogenic gas separation – Kejie , The product will supply to all over the world, such as: British, India, Burundi, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!