China New Product Nitrogen Oxygen Generator - Molecular sieve oxygen generator – can be placed in container for convenient transportation – Kejie

China New Product Nitrogen Oxygen Generator - Molecular sieve oxygen generator – can be placed in container for convenient transportation – Kejie Detail:

Product Advantage

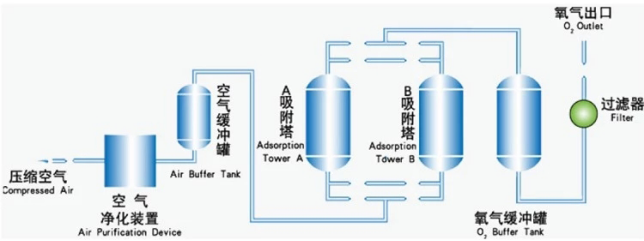

PSA process is a simple method of oxygen production, using air as raw material, energy consumption is only the electric energy consumed by the air compressor, with low operating cost, low energy consumption, high efficiency.

Mechanical and electrical integration design to achieve automatic operation

Imported PLC control automatic operation. Oxygen flow pressure purity adjustable and continuous display, can set pressure, flow, purity alarm and achieve remote automatic control and measurement, to achieve truly unmanned operation. The advanced control system makes the operation more simple, can realize unattended and remote control, and can carry out real-time monitoring of various working conditions, so as to ensure gas purity, flow stability.

High-quality components are the guarantee of stable and reliable operation

Pneumatic valves, electromagnetic pilot valves and other key components using imported configuration, reliable operation, fast switching speed, service life of more than a million times, low failure rate, convenient maintenance, low maintenance costs.

Oxygen content continuous display, over limit automatic alarm system

Monitor oxygen purity online to ensure the required oxygen purity is stable.

Advanced loading technology ensures the service life of the equipment

Zeolite molecular sieve is filled with “snowstorm” method, so that the molecular sieve is evenly distributed without dead Angle, and not easy to powder; The adsorption tower adopts multi-stage air distribution device and balance mode automatic compression device. And the zeolite molecular sieve adsorption performance to maintain a tight state, so as to ensure that the adsorption process does not produce fluidization phenomenon, effectively prolong the service life of zeolite molecular sieve.

Unqualified oxygen automatic emptying system

The low purity oxygen at the initial stage of the machine is automatically emptied, and the air is vented after reaching the target.

Ideal purity selection range

The oxygen purity can be adjusted from 21% to 93±2% according to the needs of users.

System unique cycle switching process

Reduces valve wear, prolongs equipment life and reduces maintenance costs.

Free debugging, lifelong maintenance

Strong technical strength and quality after-sales service, provide continuous technical support, users use without worries.

Product detail pictures:

Related Product Guide:

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for China New Product Nitrogen Oxygen Generator - Molecular sieve oxygen generator – can be placed in container for convenient transportation – Kejie , The product will supply to all over the world, such as: Marseille, USA, Somalia, If you need any of our products, or have other items to be produced, please send us your inquiries, samples or detailed drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.